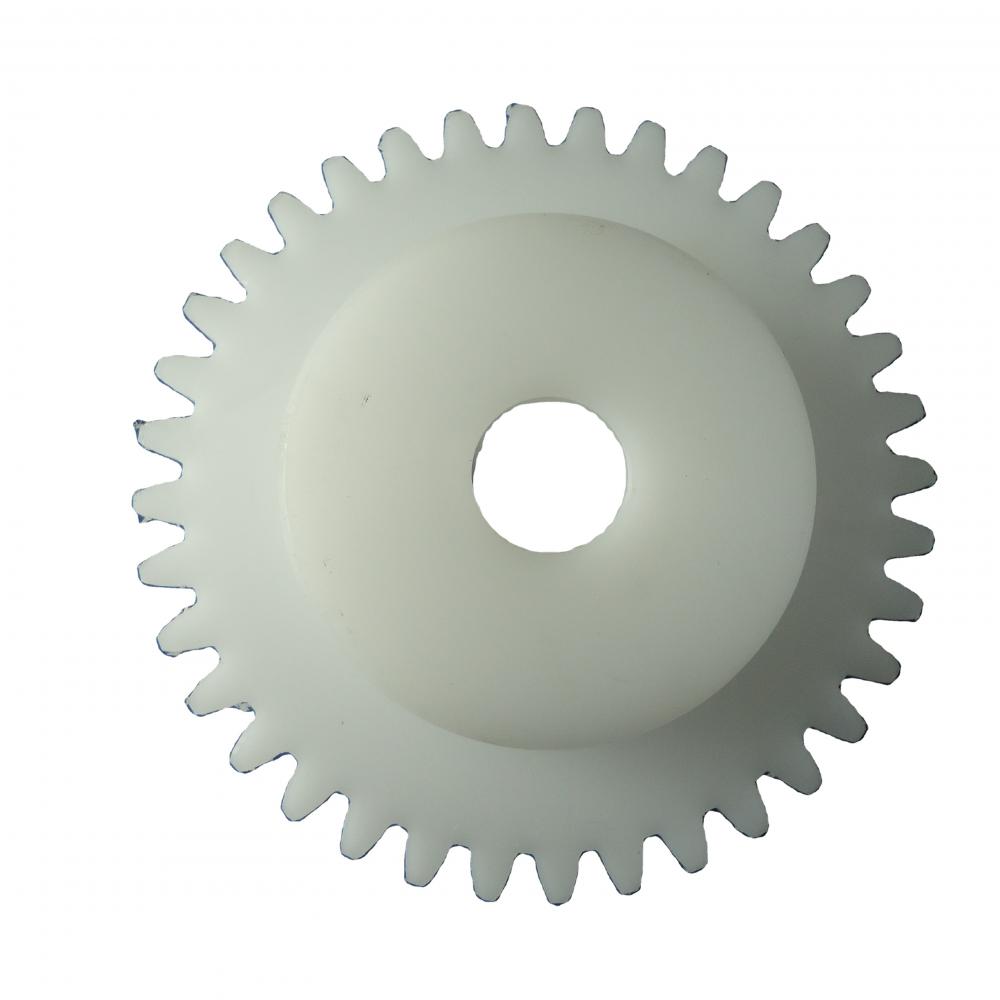

plastic spur gears Alibaba

Basic Info

Model No.: custom

Product Description

PEEK bearing, polyether ether ketone bearing, is a special engineering plastic bearing with excellent properties such as high temperature resistance, self-lubrication, easy machining and high mechanical strength. PEEK material becomes the ideal choice for durable bearings.

Polyether ether ketone bearing is a special engineering plastic bearing with high temperature resistance, self-lubrication, easy machining and high mechanical strength and other excellent performance. PEEK material can be manufactured and processed into a variety of mechanical parts, such as automobile gear, oil screen, shift start plate; Aircraft engine parts, automatic washing machine wheel, medical instrument parts, etc.

PEEK bearing is a kind of plastic bearing. Carbon fiber reinforced with graphite and PTFE lubricants, bearing grade PEEK provides the lowest coefficient of friction and the best cutting performance of all PEEK grades. The excellent combination of low friction, low wear, high LPV, low wear of fit parts and easy processing makes it an ideal choice for durable bearings, such as sleeve bearings, sliding bearings, etc.

PEEK resin has good friction resistance and mechanical properties. As the raw material of engine inner cover, bearings, gaskets, seals, clutch gear rings and other parts made with PEEK resin are widely used in automobile transmission, brake and air conditioning systems.

PEEK bearing is mainly used

1, automotive brake system parts, engine parts, transmission high temperature gasket, semiconductor tools, LCD support, chip turnover equipment, IC test equipment parts, photocopier separation claw, shaft sleeve and other office supplies high temperature parts;

2, special machinery gear, oil-free lubrication bearings, compressor valve plate, sealing ring, piston ring, valve parts, high temperature sensor probe;

3, special electronic connectors, analysis instrument parts, special cable sheath, human skeleton, hemodialysis machine parts, lithium battery sealing ring, integrated circuit film, electric iron, microwave heat resistant parts and so on.

PEEK is an ideal material for making bearings. PEEK bearings lubricate automatically once they start moving. And wear will allow the tiny bit to lubricate without any change in the bearing itself. In addition, PEEK's durability and high temperature resistance make it thinner and lighter than conventional material bearings. PEEK's lightweight nature also saves fuel, and they don't require more aluminum or steel or additional chemical additives.

FAQ

Q1:Will we Wo sign Non-Disclosure Agreements(NDA) ?

A:Yes.If it gives you peace-of-mind to sign an NDA,we are more than w ling to do so.But we have the rightkeep your design in confidential no matter NDA is signed or not.All factories are camera monitored.

Q2:How do I get a quote?

A:Please kindly provide us 3D or CAD solid model in Step, IGS,X_T format, normally Two-dimensional(2D)drawings are not adequate for accurate quoting or parts making B.Please tell us your requirement on quantisurface treatment.Color material,application enviranment for accurate pricing.

Q3:How quickly can l get my parts?

A:Quality parts can be made in 3-5 days if you provide us with complete 2Dand3DCAD models.Morecomplex parts requiring or other special features will take longer.As for shipping,most of our shipments arevia DHL, UPS,Fedex,which can take a few days from China to Europe or NorthAmerica.

Q4;How you do the quality control?

A: a.Materials inspection by IQC.

b.The fist sample inspected by QC,QC wild o over check as per the parameters list and critical dimensic requested by customers, to decide if it can go ahead for production.

c.During processing# our IP QC will check the injection molded parts every 2 hours,ensure no any rejects.

d.FQC will check the products before sending to the warehouse.

e.100% inspected by O QC before shipping out.

Contact us if you need more details on Peek Spare Part CNC Machining. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Small Plastic Gears、Making Plastic Gears. If these products fail to match your need, please contact us and we would like to provide relevant information.